Introduction

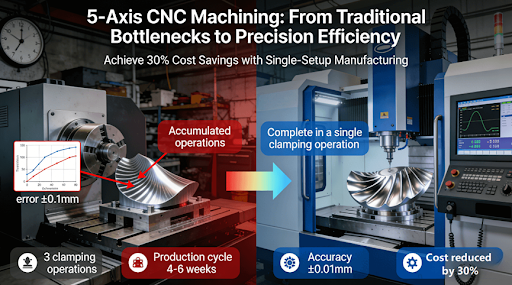

Modern manufacturing is defined by a relentless pursuit of performance, leading to parts with increasingly complex geometries — think aerospace components with aerodynamic contours or medical implants that mimic organic bone structures. However, this design evolution clashes with the limitations of traditional manufacturing methods. Conventional 3-axis CNC machining, while reliable for simpler tasks, introduces significant bottlenecks in precision, production cycles, and cost control when faced with free-form surfaces, deep cavities, or intricate details. The core issue lies in the need for multiple setups, which introduce cumulative errors and inefficiencies, ultimately restricting design freedom and inflating costs.

This article explores how 5-axis CNC machining technology provides a comprehensive solution. By enabling dynamic tool orientation and single-setup machining, it overcomes the fundamental challenges of producing complex, high-precision parts. We will delve into the technical advantages, the critical role of supporting processes like Design for Manufacturability (DFM) analysis, and how adherence to authoritative standards ensures consistent, high-quality results that can lead to significant production savings.

What Are the Key Limitations of 3-Axis CNC Machining in Complex Parts Production?

While adequate for prismatic parts, 3-axis CNC machining struggles with the demands of modern, complex components. Its inherent constraints create bottlenecks that impact quality, time, and cost.

1. The Inevitable Cumulative Error of Multiple Setups

The most significant drawback is the need for multiple setups to machine all features of a complex part. Each time a workpiece is repositioned, a new datum is established, introducing tiny but critical misalignments. These cumulative errors compound, making it nearly impossible to hold tight geometric tolerances across the entire part. This fundamentally obstructs consistent adherence to standards like ASME Y14.5, which emphasizes precise geometric dimensioning and tolerancing for reliable part function.

2. Geometric Constraints and Tool Accessibility Issues

The linear motion of 3-axis systems severely limits tool access. This leads to two major problems. First, machining curved surfaces often requires inefficient ball-end tools, which can cause poor surface finish and rapid tool wear. Second, and more critically, features like deep cavities or undercuts are often inaccessible without the toolholder colliding with the workpiece. This forces designers to split complex structures into multiple simpler parts, increasing part count, assembly steps, and potential failure points — undermining the goal of an integrated, high-strength design.

3. Inefficiency and Extended Lead Times

The Society of Manufacturing Engineers (SME) highlights that efficient machining relies on optimal tool paths and minimal non-cutting time. The 3-axis process, with its requisite multiple fixturing and repositioning, is inherently inefficient. The constant stopping, restarting, and manual handling significantly extend the total machining time and increase labor costs, making it a less viable option for both rapid prototyping and cost-effective production runs.

How Does 5-Axis CNC Machining Enable Single-Setup Manufacturing for Intricate Geometries?

5-axis CNC technology adds two rotational axes (e.g., A/C or B/C) to the standard linear motions, enabling the cutting tool to approach the workpiece from virtually any direction. This transformative capability is the key to overcoming the limitations of traditional methods.

- The Mechanics of Multi-Axis Motion Kinematics: In a typical 5-axis machine, the two rotational axes allow for continuous, dynamic adjustment of the tool’s orientation relative to the workpiece. This means the tool’s tip and its side can be used effectively, maintaining an optimal cutting angle across complex contours. This dynamic control is the foundation of true single-setup machining, where the entire part is finished without being removed from the machine bed.

- Achieving Unmatched Precision and Geometric Freedom: By maintaining a single datum throughout the entire machining process, 5-axis technology eliminates the repositioning errors inherent in 3-axis machining. This ensures all features are machined relative to one consistent coordinate system, dramatically enhancing accuracy. Furthermore, it unlocks unprecedented geometric freedom, allowing for the seamless production of complex features like impeller blades or turbine wheels that would be impossible to machine as a single piece with traditional methods. Utilizing a 5-axis CNC machining service is often the most practical way to access this capability without major capital investment.

- Tangible Efficiency Gains and Cost Reduction: The practical benefits are substantial. For instance, a turbine blade that required three separate setups and 12 hours on a 3-axis machine can often be completed in a single setup in under 6 hours using 5-axis technology. This consolidation of operations reduces idle time, minimizes manual handling, and can lead to cost savings of over 30% by slashing labor and machine time.

What Core Capabilities Should a High-Quality 5-Axis Machining Provider Possess Beyond Equipment?

Owning advanced machinery is only one part of the equation. A superior provider differentiates itself through expertise, systems, and a commitment to quality that goes far beyond the machine tool itself.

1. Advanced CAM Programming and Simulation

The full potential of a 5-axis machine is only realized with sophisticated Computer-Aided Manufacturing (CAM) software. Experts use programs like Siemens NX or CATIA to generate optimized, collision-free toolpaths that smoothly manage the simultaneous movement of all five axes. Integrated simulation tools are crucial for visualizing the entire process and detecting potential collisions before any metal is cut, ensuring safety and preventing costly errors.

2. Rigorous Quality Management and Certification

For high-stakes industries, a provider’s quality management system is non-negotiable. Certifications like ISO 9001:2015 are not just badges on a wall; they represent a systematic approach to quality that ensures consistency and traceability. This is especially critical for complex components where failure is not an option. Leading manufacturers leverage these systems to embed quality checks throughout the production process.

3. Expertise in Fixture Design and Metrology

The ability to design and manufacture efficient, rigid fixtures is critical for stabilizing parts during the high dynamic forces of 5-axis machining. Furthermore, a high-quality provider will employ advanced metrology — using tools like on-machine probes and Coordinate Measuring Machines (CMMs) — to verify that every part meets the specified tolerances, creating a closed-loop system that guarantees precision.

How Can DFM Analysis Optimize Cost-Effectiveness in 5-Axis CNC Projects?

Design for Manufacturability (DFM) is a collaborative engineering process that optimizes a part design for the chosen manufacturing method. In 5-axis machining, a thorough DFM analysis is a powerful tool for driving down costs and improving outcomes.

1. Consolidating Parts and Simplifying Assemblies

One of the most significant cost-saving opportunities DFM uncovers is the ability to consolidate multiple components into a single, monolithic part. Because 5-axis machining can access nearly every surface, complex assemblies that were once necessary can be redesigned as one piece. This reduces part count, eliminates assembly labor, and improves the overall strength and reliability of the final product.

2. Optimizing Toolpaths and Material Usage

A DFM analysis conducted by experienced engineers can suggest subtle design tweaks that dramatically improve machining efficiency. This might involve adjusting fillet radii to allow for standard tooling or slightly altering a wall angle to enable a more efficient toolpath. These small changes, when applied to an entire production run, can result in substantial savings in machining time and material waste.

3. Facilitating Rapid and Accurate Quoting

Engaging a provider that offers Online Custom 5-Axis CNC Machining Services with integrated DFM feedback streamlines the entire process. By submitting a CAD model, engineers can receive an instant review that highlights potential production issues and provides a cost-effective design optimization before the project even begins, ensuring clarity and avoiding surprises down the line.

How Does Advanced Quality Control Ensure Precision in Complex Component Manufacturing?

Precision is meaningless without verification. A robust quality control (QC) system is essential for manufacturing complex components, particularly for regulated industries like aerospace and medical devices.

- In-Process Monitoring and Closed-Loop Control: Advanced manufacturing leverages in-process measurement technologies, such as on-machine probes, to inspect critical dimensions without removing the part. This data can be fed back to the machine control to automatically compensate for tool wear or thermal drift, creating a closed-loop system that maintains tolerances within microns throughout a production run.

- Final Inspection and Digital Traceability: Post-machining, a comprehensive inspection using CMMs or laser scanners validates the part against the original CAD model. The resulting data and deviation reports are archived for full digital traceability, a requirement under standards like AS9100 for aerospace. This ensures that every component’s history is documented, from raw material to finished part.

- Adherence to National and International Standards: Following guidelines from institutions like the National Institute of Standards and Technology (NIST) ensures that measurement science and standards are applied correctly. This commitment to standards-based manufacturing provides a foundation of trust and reliability, guaranteeing that parts will meet exact specifications and perform as intended in the field.

Conclusion

5-axis CNC machining has evolved from a niche technology to a core manufacturing solution for overcoming the challenges of complex part production. By enabling single-setup precision, unlocking new design freedoms, and integrating with rigorous quality management and DFM practices, it directly addresses the inefficiencies and cost drivers of traditional methods. As a cornerstone of smart manufacturing, it empowers companies to innovate faster, produce more reliably, and achieve significant competitive advantage through reduced costs and shortened time-to-market.

FAQs

Q: What is the typical lead time for a 5-axis CNC machining project?

A: Lead times vary based on complexity, but with advanced scheduling, prototypes can be delivered in as little as 1-3 days. For mass production, timelines are optimized through DFM analysis to ensure efficiency without compromising quality.

Q: How does 5-axis machining compare in cost to traditional methods for small batches?

A: While initial setup may be higher, 5-axis reduces multiple setups and tooling costs, making it cost-effective for small batches by cutting total production time by up to 30%.

Q: Can 5-axis CNC handle materials beyond metals, like composites?

A: Yes, it supports engineering plastics and composites. Techniques like low-temperature cutting prevent deformation, ensuring precision for diverse materials.

Q: What file formats are required for online quoting?

A: Common formats include STEP, IGES, or STL. Uploading these allows for instant DFM feedback and accurate pricing.

Q: How is intellectual property protected during collaboration?

A: Strict protocols like NDAs and encrypted data transmission are used, ensuring designs remain confidential and secure throughout the process.