Introduction

The automotive manufacturing industry universally faces the significant challenges of high parts production costs and long delivery cycles. Traditional methods like manual machining or basic machine tools are often inefficient, leading directly to project delays and budget overruns. The root causes of these issues include outdated technology, a lack of optimized processes, and insufficient quality control, making it difficult for enterprises to adapt to rapid market changes. This article will explain how CNC machining technology integrates Advanced Manufacturing Technology and Innovative Design Solutions to achieve cost optimization through automation and precision engineering. The following content will provide an in-depth analysis of the core advantages and practical applications of CNC machining.

What is CNC machining, and how does it enhance manufacturing efficiency?

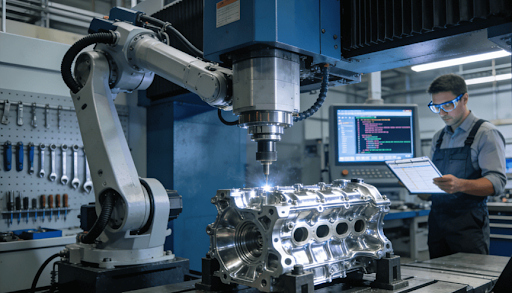

So, what does CNC machining stand for? It stands for Computer Numerical Control machining, a manufacturing process where pre-programmed computer software dictates the movement of factory machinery and tools. This automation enables the production of complex parts with a high degree of accuracy and repeatability, far surpassing the capabilities of traditional manual methods.

The core principle involves converting a 3D digital model into a set of instructions (G-code) that controls the movement of cutting tools along multiple axes, precisely removing material from a solid block to create the final part. This level of automation eliminates human error and inconsistency. According to a report on precision manufacturing standards by the International Academy for Production Engineering (CIRP), the use of Advanced Manufacturing Technology like CNC allows for tolerances to be consistently held within micrometer levels, ensuring every part is identical to the digital prototype.

The efficiency gains are realized through the application of advanced CNC machining tools, particularly multi-axis machining centers. A 5-axis machine, for instance, can process five sides of a part in a single setup, eliminating the need for manual repositioning and multiple machine setups. This dramatically reduces processing time for complex automotive components from hours to minutes, streamlining the entire production workflow and paving the way for high-volume, high-quality manufacturing.

Why can CNC machining significantly reduce automotive part costs?

The cost advantage of CNC machining is not from a single source but is achieved through a systematic approach to cost reduction across the manufacturing lifecycle.

Direct Cost Reduction through Material and Labor Efficiency

CNC programming optimizes tool paths to maximize material usage, significantly reducing waste. Furthermore, high automation minimizes the reliance on skilled manual labor for each part, cutting down on per-unit labor costs. While the initial CNC machining center price may be a considerable investment, the long-term reduction in piece-part cost and increase in production capacity offer a compelling return on investment.

Unleashing Cost-Saving Potential through Design Innovation

Cost control begins at the design stage. Innovative Design Solutions, such as lightweight topology optimization and part consolidation (combining multiple components into a single CNC machined part), reduce part count and simplify assembly without compromising strength. These designs often feature complex geometries that are ideally suited for CNC machining. Selecting optimized materials in compliance with standards from bodies like ASTM International further ensures performance and controls material costs.

-

Optimized Material Usage

CNC precision minimizes raw material waste, directly impacting the bottom line, especially when using expensive alloys.

-

Reduced Assembly and Labor Costs

Part consolidation simplifies the supply chain and assembly process, leading to significant overall savings.

The Supply Chain Advantage of Sourcing from China

In the global manufacturing landscape, CNC machining china represents high cost-effectiveness and robust supply chain capabilities. China’s mature manufacturing ecosystem offers competitive pricing and a one-stop solution from rapid prototyping to mass production. This inherent supply chain efficiency is a major cost advantage. In contrast, traditional methods like manual lathes are less flexible and capable for complex parts, a point elaborated in the comparison of CNC Machining vs. Lathe Tools.

How to achieve rapid delivery within 5 days using CNC machining?

In the fast-paced automotive industry, CNC machining is a key enabler for achieving rapid delivery within 5 days. This speed is made possible by seamless digitalization and automation.

The process starts with a digital 3D design model, which can be directly converted into machine code using CAM software, eliminating the need for physical molds or complex fixtures. When combined with Rapid Prototyping Methods, design verification and modifications can be completed in a matter of days, drastically accelerating the product development cycle.

During production, the integration of CNC machining and manufacturing systems shows its power. Automated tool changers, pallet systems, and continuous operation capabilities allow machines to run 24/7. For many low-to-medium volume automotive parts, the entire process from order confirmation and programming to production and shipping can be completed within a tight 3-5 day schedule. This entire workflow adheres to quality management systems like ISO 9001, ensuring that speed does not come at the expense of quality.

What are the innovative applications of CNC machining in the automotive manufacturing industry?

CNC machining applications in automotive manufacturing have expanded from basic components to enabling cutting-edge design and performance.

Dedicated CNC machine for automotive parts can produce a wide range of critical components, from engine blocks and transmission housings to turbocharger impellers and precise braking system components. In the electric vehicle sector, CNC technology is used for battery enclosures, motor housings, and heat sinks for power electronics, which demand extreme precision and thermal management.

These applications rely on top-tier Precision Engineering Services to ensure parts meet micron-level tolerances, excellent surface finishes, and strict geometric consistency. To guarantee absolute reliability in mass production, the entire machining process follows stringent Quality Control Standards such as IATF 16949. These standards cover the entire process from raw material inspection to final part validation, ensuring every component meets the automotive industry’s durability and safety requirements. For instance, a service provider like JS Precision not only adheres to automotive standards but also leverages its AS9100D aerospace certification to deliver quality that exceeds expectations for automotive clients, ensuring aerospace-grade quality for critical components.

When investing in a CNC machining center, how to evaluate price versus value?

For companies considering bringing CNC capabilities in-house, a rational evaluation of the CNC machining center price versus long-term value is critical.

Analyzing the Total Cost of Ownership

The assessment should look beyond the initial price tag. The Total Cost of Ownership includes:

- Initial Investment and Tech Support: The machine’s base price, brand premium, required software, and training costs.

- Operational and Maintenance Costs: Energy consumption, tooling wear, regular maintenance, and potential upgrade expenses.

Quantifying Value and Return on Investment

The true decision should be based on value output. The value delivered by CNC machining centers is reflected in:

- Production Efficiency and Flexibility: Drastically reduced machining times, the ability to handle complex designs, and quick changeover capabilities allow companies to seize more market opportunities.

- Quality Cost Savings: Near-zero scrap rates and reduced inspection and rework directly save hidden costs.

- Technology Forward-Looking: Investing in smart machines integrated with IoT and data monitoring—hallmarks of Advanced Manufacturing Technology—lays the foundation for the digital factory of the future. As indicated by CIRP data, companies investing in advanced manufacturing technologies show significantly higher long-term productivity and competitive gains.

H2:Conclusion

In summary, CNC machining technology, with its core advantages of automation, high precision, and flexibility, provides a practical and effective solution to the long-standing challenges of cost and efficiency in automotive manufacturing. It is not merely a replacement for traditional processes but a strategic asset that drives innovative design, enables precision engineering, and builds sustainable competitiveness.

Immediately consult with a manufacturing expert to obtain a personalized CNC machining solution and take the critical step toward optimizing your next project.

FAQs

Q1: What is the basic principle of CNC machining?

A: CNC machining uses computer programs to control machine tools, automatically cutting materials to create high-precision parts. It is more efficient than manual operation, with an error rate of less than 0.01%, making it suitable for complex designs.

Q2: How does CNC machining help reduce costs?

A: By automating processes, it reduces labor and material waste. Design optimization can save up to 40% in costs. Combined with batch production, the long-term return on investment is significant.

Q3: What are the key standards for CNC machining of automotive parts?

A: Standards like IATF 16949 must be met to ensure durability. Precision engineering services can handle high-temperature materials to meet safety requirements.

Q4: What is the price range for a CNC machining center?

A: Prices vary based on size and functionality, with basic models starting from $50,000. It is advisable to evaluate the lifecycle cost, not just the initial investment.

Q5: How to choose a reliable CNC machining service provider?

A: Check for certifications like ISO 9001 and review case studies. Prioritize suppliers that offer rapid prototyping and robust quality assurance to ensure project success.